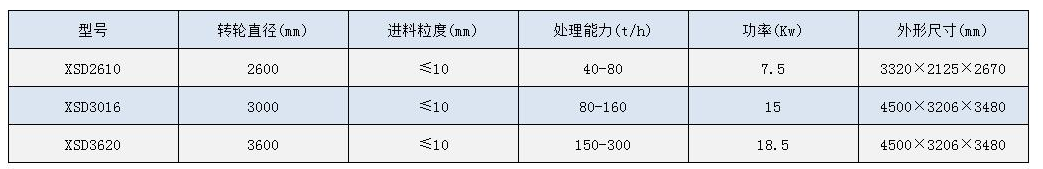

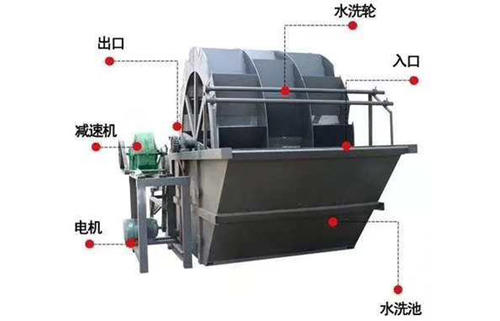

Wheel bucket sand washer

- 60s quick Q & A

- 30min reply

- 24h free program

Product overview:

Sand washing machine is also called wheel bucket sand washing machine. It is a high-efficiency wheel bucket sand washing machine used with sand making machine based on the original XSD wheel bucket sand washing machine and combined with the actual situation of sand and gravel industry at home and abroad. It has the characteristics of high washing purity, reasonable structure, large processing capacity, low power consumption, less sand loss and low failure. It is the preferred choice for the upgrading of domestic sand washing machine equipment.

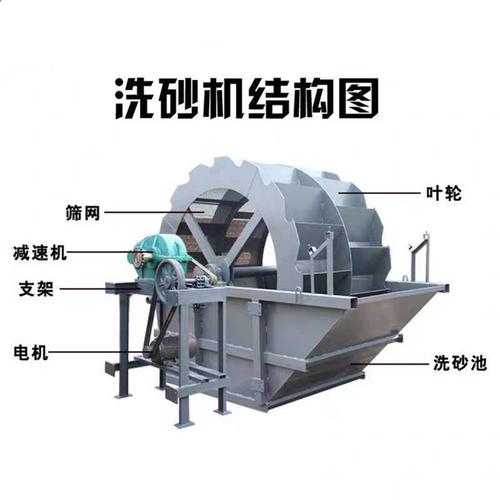

The sand washing machine is mainly composed of the following parts:

1. Transmission device: it is composed of motor, large and small pulley, V-belt and gear reducer. Gear reducer: speed ratio i = 48.57. Totally enclosed oil bath type. The gear is a heat-treated steel cylindrical helical gear. Both ends of the shaft are supported by tapered roller bearings. The material of reducer box is HT20-40, and the joint surface is lined with δ= 0.5mm industrial liner paperboard and apply sealant to prevent lubricating oil leakage of the reducer. The reasonable design and careful processing of the gear and reducer box ensure the transmission accuracy of the reducer.

2. Spiral shaft: spiral diameter d = 1122mm, pitch s = 500mm, number of heads z = 1, number of turns n = 15.5, right-handed, edging spiral. Spiral blade material is Q235A, δ= 8mm steel plate is pressed with a special die and continuously welded on the hollow shaft. The spiral of each pitch is composed of six fan-shaped lining plates made of high manganese cast steel (ZGMn13). It has good wear resistance and durability. When it is worn out of use, a new lining plate can be replaced. The spiral

lining plate is connected with the spiral blade with screws, nuts and spring coil, which is installed on the forward side of the spiral and overlaps with the spiral blade, so that the spiral blade can be well protected. Hollow shaft is Φ three hundred and seventy-seven × 15 seamless steel pipe, ensuring sufficient strength and stiffness, and flange plates are welded at both ends, which are

respectively connected with the connecting plate and the lower bearing. This structure completely meets the washing, sorting, grading and dewatering of sand and gravel.

3. Lower bearing: the lower end of the spiral shaft is below the water line of the water tank and is supported by the lower bearing. All the axial force of the helical shaft is borne by the rolling bearing of the output shaft of the gear reducer. The lower bearing does not bear axial force, but only radial force. The lower bearing is installed outside the lower side of the water tank.

The tail shaft is connected with the spiral shaft. When working, it rotates in a flexible rubber sealing ring. The retaining ring rotating with the tail shaft ensures that the lower bearing can still be sealed well after long-term use.

4. Water tank: including shell, left and right weir plates, feeding device, etc.

The water tank is made of steel plate and connected into a rigid impermeable structure by electric welding. The left and right weir plates and feeding devices are connected with the shell with bolts, nuts and spring washers, and the left and right weir plates are lined with shell bodies δ= 3mm rubber plate to seal.

A bending plate is installed on one side of the bottom of the water tank to maintain an appropriate gap between the groove bottom and the outer edge of the blade, so as to facilitate the spiral blade to push the particles forward. The opposite side is a drainage ditch, which is used to discharge the water from the sand and stone. This design enables the water released by the spiral blade in the process of promoting sand and gravel to be discharged at one side of the water tank rather than through the material behind.

The overflow weir plate can be adjusted. Lifting one or two weir plates can shorten the effective length of the weir plate. By changing the entry speed of the cleaning water, the water head can be increased and the overflow speed of the cleaning water can be changed. The fine particles can be removed according to the needs of classification for classification.

The weir plate can also provide compensation for the inclination of the sink position caused by assembly or installation errors. The sand and stone to be washed enters the washing machine from the feeding device. It has no internal and external baffles, which can effectively control the material flow and reduce the flow rate. When the feeding device is installed at the correct position, the sand and stone will enter the washing machine and be evenly distributed, and the eddy current will be reduced, which is conducive to the maintenance of fine particles.

Performance characteristics

1. The washing height of the sand washing machine is high, and there is less sand loss in the sand washing process. Especially, the transmission part is isolated from water and sand, so the failure rate of the sand washing machine is much lower than that of the common sand washing machine.

2. Reasonable structure, novel sealing structure, fully enclosed oil bath transmission device and adjustable overflow weir plate ensure the efficiency and durability of this series of products, good cleaning and dehydration effect and stable fine-grained products.

3. Large processing capacity and low power consumption.

4. Water saving and durable.

5. Simple maintenance.

6. The loss of medium fine sand and stone powder is small, and the gradation and fineness modulus of washed building sand meet the national standards of building sand and building pebble and gravel. The machine has almost no wearing parts except screen.

7. Long service life, no maintenance for a long time.