Flotation machine

- 60s quick Q & A

- 30min reply

- 24h free program

Product introduction:

Flotation machine is the main equipment to realize the flotation process. The motor is driven by the trigonometric transmission of the motor to drive the impeller to rotate, resulting in centrifugal action to form negative pressure, inhaling sufficient air to mix with the ore pulp, mixing the slurry with the medicine, and refining the foam, so that the mineral adheres to the foam and floats to the slurry surface to form a mineralized foam. Among the components of flotation machine, impeller and stator are vulnerable components.

Product introduction:

Flotation machine is the main equipment to realize the flotation process. The impeller is driven to rotate by the triangular drive of the motor, resulting in centrifugal action, forming a application scope:

It is suitable for recovering useful minerals, separating ferrous metals, non-ferrous metals, precious metals, non-metallic minerals and chemical raw materials.

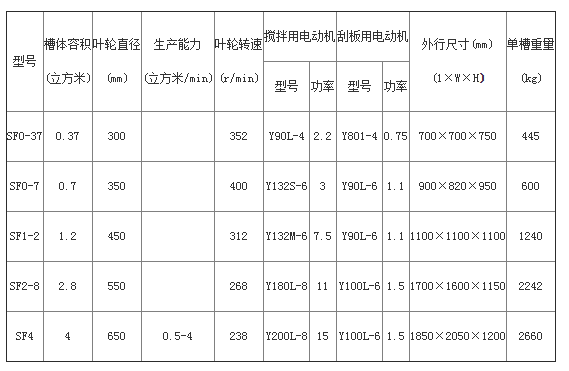

Introduction to SF flotation machine:

SF flotation machine is used to separate ferrous metals, non-ferrous metals, precious metals, chemical raw materials and non-metallic minerals and recover useful minerals. The device has large suction capacity and low power consumption. The impeller is equipped with backward inclined upper and lower blades. The upper blade generates pulp up circulation, and the lower blade generates pulp down circulation. Each tank has the triple functions of suction, pulp suction and flotation. It forms a flotation circuit without any auxiliary equipment. The horizontal configuration is convenient for the change of process. The pulp circulation is reasonable and can reduce the coarse sand sedimentation to a certain extent. In addition, the equipment is also equipped with automatic control device for pulp surface, which can be adjusted conveniently. Negative pressure, inhalation of adequate air mixed with ore pulp, mixing slurry with drugs, and refining foam, so that the mineral adhesion foam above, floating to the slurry surface and then form a mineralized foam. Among the components of flotation machine, impeller and stator are vulnerable components.

Main components:

The flotation machine is driven by the triangle belt of the motor to drive the impeller to rotate, resulting in centrifugal action to form negative pressure. On the one hand, the air is mixed with the slurry by inhaling sufficient air. On the one hand, the slurry is mixed with the medicine, and the foam is refined at the same time, so that the mineral adheres to the foam and floats to the slurry surface to form a mineralized foam. Adjust the height of the gate and control the liquid level, so that the useful foam is scraped out by the scraper.

working principle:

After the coal slime and reagent are fully mixed, they are fed to the bottom of the tank in the first chamber of the flotation machine. After the impeller rotates, a negative pressure is formed in the wheel cavity, so that the pulp under the tank and in the tank enters the mixing area from the lower suction port and the upper suction port of the impeller respectively, and the air enters the mixing area along the air guide sleeve, where the pulp, air and reagent are mixed. Under the action of centrifugal force of impeller, the mixed pulp enters the mineralized area, the air forms bubbles and smashed, and is fully contacted with the coal particles, forming a mineralized bubble. Under the action of the stator and turbulent plate, it distributes evenly in the cross section of the tank, and moves upward into the separation area, and the rich aggregate forms a foam layer, which is discharged by the scraping bubble mechanism to form a clean coal foam. The non mineralized coal particles on the tank bottom will be mixed, mineralized and separated again through the circulation hole and upper suction port. Part of the slurry not sucked by the impeller under the tank enters under the tank of the second chamber through the medium ore box buried in the slurry. After completing the whole process of the first chamber, it enters the third chamber. The flotation machine repeats this cycle. After passing through the second chamber, the slurry enters the tailings tank to discharge the end tailings.

Main features:

1. Large suction capacity and low power consumption.

2. Each cell has the triple functions of suction, slurry suction and flotation. It forms a flotation circuit without any auxiliary equipment. It is horizontally configured to facilitate the change of process.

3. The slurry circulation is reasonable, which can reduce the coarse sand sedimentation to the limit.

4. It is equipped with automatic control device for pulp surface, which is convenient to adjust.

5. The impeller is equipped with backward inclined upper and lower blades. The upper blade generates pulp up circulation, and the lower blade generates pulp down circulation.

- Prev:no more

- All

- Next:Mixing drum