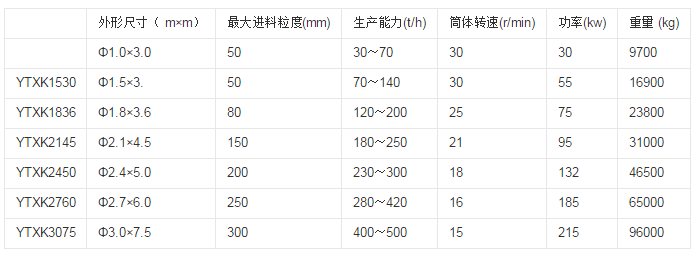

Cylinder stone washing machine

- 60s quick Q & A

- 30min reply

- 24h free program

Cylinder washing machine

The equipment is widely used for various difficult to wash large ores. The ore washing machine is divided into cylinder type and cylinder plus screen strip type. The latter can divide the washed materials into two levels of products + 40mm and - 40mm, and - 40mm can be further scrubbed by the double spiral groove ore washer. The materials can be divided into two levels of products + 2mm and - 2mm, and the ore washing efficiency can reach about 98%. This combination is a very effective method for difficult to wash ores.

structure

It is mainly composed of. The cylinder is composed of slurry making section and screen section, and wear-resistant rubber (polyurethane wear-resistant sheet) is used as lining plate in thecylinder.

working principle:

The cleaning cylinder is supported by four tugs, the motor drives the reducer, and the large and small gears drive the cleaning cylinder to rotate at low speed. The ore containing mud and stone powder is fed from the feed inlet and enters the rotating drum. A wear-resistant rubber lining plate with a certain angle is installed in the cleaned drum, which is continuously lifted and thrown down. It circulates for many times during the movement from the feed end to the discharge end, and is washed and washed by forward or reverse flushing water. The cleaned ore is lifted by the elevator and discharged into the double-layer conical screen, which is divided into coarse, medium The fine particles are discharged respectively. The wastewater containing sludge flows out through the perforated baffle at the discharge or feed end.

Measures to improve efficiency:

Modification of lining plate of cylindrical ore washing machine

In order to prolong the ore washing time in the slurry making section and enhance the friction between the ore and the lining plate, through research and test, the wear-resistant rubber obtained by adopting the unique wet formula design and nano composite dispersion technology has excellent wear resistance, strength and elasticity and long service life. This rubber wave lining plate is used to replace the smooth arc lining plate, Convex lines and roughness are added on the new lining plate. After using the wear-resistant rubber lining plate of the cylinder washing machine, the effective time of ore slurry making in the cylinder washing machine is prolonged, the ore is fully soaked and scrubbed, and the ore washing efficiency is improved. At the same time, due to the enhanced wear resistance of the lining plate, the service life is prolonged and the cost is reduced.

Heighten the height of the retaining ring at the ore outlet end of the cylindrical washing machine

Because the cylinder washing machine does not have strong crushing and dispersing effect on lump ore slime mass when dealing with difficult to wash ore with high mud content and large slime plasticity index, the desliming effect of lump ore on the screen is poor. In order to prolong the effective ore washing time of lump ore and make the lump ore fully scrubbed, the screen sectional ore discharge retaining ring of the cylindrical ore washing machine is raised. In this way, the effective ore washing time of lump ore in the cylindrical ore washing machine is prolonged and the desliming effect of lump ore is improved.

Change the rotating speed of drum washer

When the rotating speed of the drum washer decreases, it has a great negative impact on the ore washing effect of the trough washer in the next process. With the increase of ore feeding, the mud content of the trough washer in the next process increases sharply. The main reason is that when the rotating speed of the cylindrical ore washing machine decreases, the role of ore lifting and scrubbing is weakened, and the fine ore enters the screen section of the cylindrical ore washing machine, that is, it falls from the screen strip and enters the tank washing machine of the next process, which greatly shortens the scrubbing time of the fine ore in the cylindrical ore washing machine, and the surface is tightly wrapped by clay, which seriously affects its ore washing effect.

- Prev:Integrated sand washing machine

- All

- Next:no more