Jaw crusher

- 60s quick Q & A

- 30min reply

- 24h free program

Product introduction:

Jaw crusher is commonly known as jaw broken, also known as tiger mouth. The crusher is composed of two jaw plates, a moving jaw and a static jaw, to simulate the movement of two jaws of animals and complete the material crushing operation. It is widely used for crushing various ores and large materials in mining smelting, building materials, highway, railway, water conservancy and chemical industries. The highest compressive strength of the crushed material is 320MPa.

This series of products have the characteristics of large crushing ratio, uniform product size, simple structure, reliable operation, simple maintenance and economic operation cost. It is widely used in many departments such as mining, smelting, building materials, highway, railway, water conservancy and chemical industry to crush various materials with compressive strength not exceeding 320 MPa.

Jaw crusher has the characteristics of large crushing ratio, uniform product particle size, simple structure, reliable operation, simple maintenance and economic operation cost. Jaw crushers are widely used in many departments such as mining, smelting, building materials, highway, railway, water conservancy and chemical industry to crush all kinds of materials with compressive strength not exceeding 320 MPa.

Jaw crusher - also known as tiger mouth. The crusher is widely used because of its simple structure and reliable operation. It is used to crush hard and medium hard materials. In the concentrator, it is mostly used as coarse crushing and medium crushing equipment.

In the process of crushing ore by jaw crusher, the materials added to the crushing chamber of jaw crusher (the space composed of fixed jaw plate and movable jaw plate) are crushed by crushing, splitting and bending when the movable jaw plate is close to the fixed jaw plate due to the periodic reciprocating swing of the movable jaw plate. When the movable jaw leaves the fixed jaw, the materials that have been crushed to less than the size of the ore discharge port are discharged from the lower ore discharge port by their own weight. The material located at the upper part of the crushing chamber that has not been crushed to a small enough size will then fall to the lower part of the crushing chamber and continue to be crushed under the action of the jaw plate again.

Product classification:

As far as jaw crushers are concerned, although the structural types are different, their working principles are basically similar, but the moving trajectory of the moving jaw is different. In short, when the movable jaw plate makes periodic reciprocating motion to the fixed jaw plate around the suspension shaft, sometimes approaches and sometimes leaves, and when the movable jaw plate approaches the fixed jaw plate, the ore between the two jaw plates is broken by the combined action of crushing, splitting and bending breaking; When the movable jaw leaves the fixed jaw, the crushed ore is discharged through the ore discharge port of the crusher under the action of gravity.

Principle of single swing jaw type:

The movable jaw is hung on the spindle and can swing left and right. When the eccentric shaft rotates, the connecting rod reciprocates up and down, driving the two thrust plates to reciprocate, so as to promote the moving jaw to reciprocate left and right, so as to realize crushing and unloading. This crusher adopts crank double connecting rod mechanism. Although there is a great crushing reaction force on the moving jaw, the eccentric shaft and connecting rod bear little force. Therefore, it is mostly made into large-scale machines and medium-sized machines in industry to crush hard materials. In addition, when the crusher works, the motion track of each point on the moving jaw is an arc centered on the mandrel, the arc radius is equal to the distance from the point to the axis, the upper arc is small, the lower arc is large, the crushing efficiency is low, and the crushing ratio is generally 3-6. Because of the simple movement track, it is called simple swing jaw crusher.

Simple pendulum jaw crusher has compact and simple structure, and the force of transmission parts such as eccentric shaft is small; Due to the small vertical displacement of the moving jaw, less materials are excessively broken during processing, and the wear of the moving jaw plate is small.

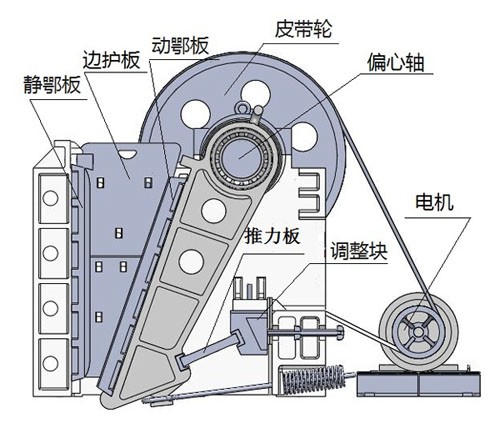

Principle of compound pendulum jaw type:

The upper end of the movable jaw is directly suspended on the eccentric shaft as the connecting rod of the crank connecting rod mechanism, which is directly driven by the eccentricity of the eccentric shaft, and the lower end of the movable jaw is hinged with the thrust plate and supported on the rear wall of the frame. When the eccentric shaft rotates, the motion trajectory of each point on the movable jaw gradually changes from the circumference of the suspension point (the radius is equal to the eccentricity) to an ellipse. The more it moves towards the lower part, the more the ellipse deviates until the trajectory of the connecting point between the lower part and the thrust plate is a circular arc. Because the movement track of each point on the moving jaw in this machine is relatively complex, it is called complex swing jaw crusher.

Compared with the simple pendulum jaw crusher, the compound pendulum jaw crusher has the advantages of lighter weight, fewer components, more compact structure, better filling degree in the crushing chamber, uniform crushing of the loaded material blocks, and forced unloading of finished products at the lower end of the moving jaw, so the productivity is higher, which is 20-30% higher than that of the simple pendulum jaw crusher of the same specification; The material block has a large up and down rolling movement at the lower part of the moving jaw, which is easy to unload in the shape of a cube

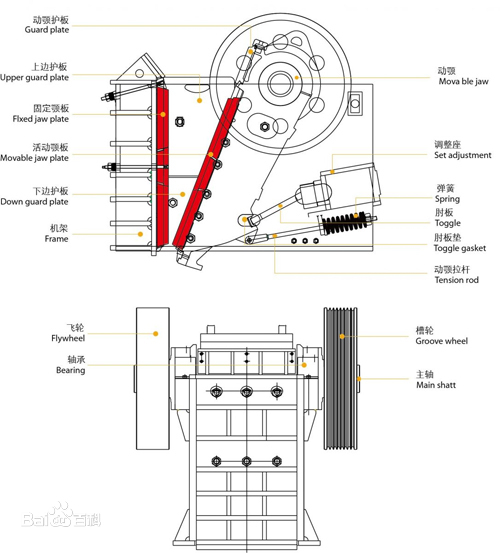

Product structure diagram:

(attached figure)

Jaw crusher is mainly composed of fixed jaw plate, movable jaw plate, frame, upper and lower guard plates, adjustment seat, movable jaw pull rod, etc. A good understanding of the internal structure of jaw crusher can help jaw crusher in the process of use and in case of problems.

Crushing ratio:

Crushing ratio is an important evaluation index to measure jaw crusher. The crushing ratio of jaw crusher is the ratio of raw material particle size to product accuracy after crushing. It indicates the degree of reduction of raw materials after crushing. After the ore is crushed, the particle size becomes smaller. The ratio of particle size before ore crushing to particle size after crushing is called crushing ratio. It represents the multiple of particle size reduction after ore crushing. The calculation methods of crushing ratio are as follows:

1. The maximum particle size method is calculated by the maximum particle size before ore crushing and the maximum particle size after ore crushing. This calculation method is often used in the design of concentrator in China, because the width of ore feeding mouth of jaw crusher should be determined according to the maximum particle size

2. The ratio between the effective width of the feed port and the width of the discharge port of the jaw crusher is used. The discharge particle size of some jaw crushers is not determined by the size of the discharge port.

3. It is calculated by the average particle size before and after ore crushing, also known as the average crushing ratio

Product features:

1. Low noise and less dust.

2. Its crushing ratio is large and the particle size of the product is uniform.

3. The utility model has the advantages of simple structure, reliable operation and low operation cost.

4. The lubrication system is reliable, the replacement of parts is convenient, and the equipment maintenance is simple.

5. The crushing cavity is deep and has no dead zone, which improves the feeding capacity and output.

6. Equipment energy saving: single machine energy saving is 15% ~ 30%, and the system energy saving is more than twice.

7. The adjustment range of discharge port is large, which can meet the requirements of different users.

working principle:

When the jaw crusher works, the movable jaw plate makes periodic reciprocating motion to the fixed jaw plate, sometimes approaching and sometimes leaving. When approaching, the material is crushed by extrusion, splitting and impact between the two jaw plates; When leaving, the crushed materials are discharged from the discharge port by gravity.

In the process of crushing huge stones into small stones, the first crusher is usually the "main" crusher. History longest, also very strong crusher is jaw crusher. When feeding the jaw crusher, the material is poured into the crushing chamber containing jaw teeth from the top inlet. The jaw teeth push the material against the chamber wall with great force to crush it into smaller stones. Supporting the movement of jaw teeth is an eccentric shaft, which runs through the fuselage frame. Eccentric motion is usually generated by flywheels fixed at both ends of the shaft. Flywheel and eccentric support bearings often use spherical roller bearings, which must bear huge impact load, abrasive sewage and high temperature.

- Prev:Sanding machine

- All

- Next:Counterattack break