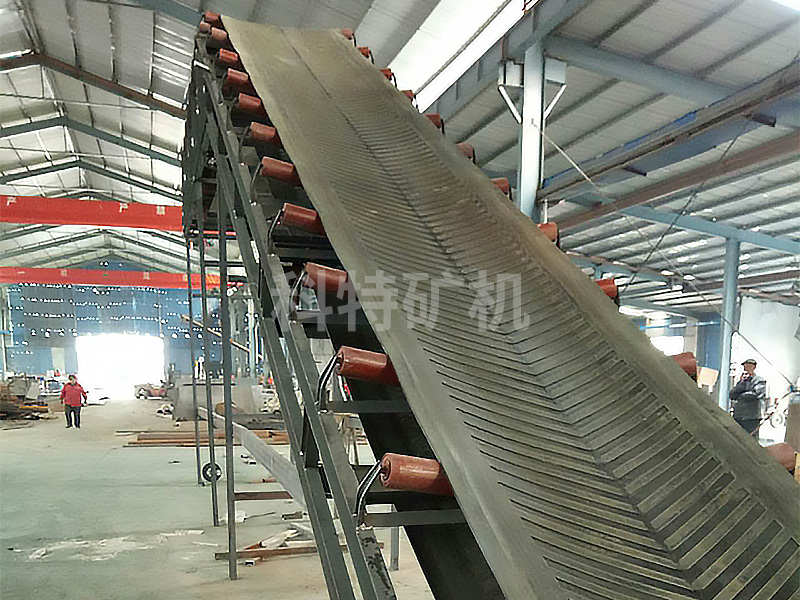

Belt conveyor

- 60s quick Q & A

- 30min reply

- 24h free program

Product introduction:

Belt conveyor, also known as belt conveyor, is widely used in household appliances, electronics, electrical appliances, machinery, tobacco, injection molding, posts and telecommunications, printing, food and other industries, as well as the assembly, testing, commissioning, packaging and transportation of objects. Line conveying can be selected according to process requirements: ordinary continuous operation, beat operation, variable speed operation and other control modes; The line body shall be selected according to local conditions: straight line, curve, slope and other line forms. The conveying equipment includes: belt conveyor, also known as belt conveyor or belt conveyor. It is an indispensable economic logistics conveying equipment to form a rhythmic flow line. According to its conveying capacity, belt conveyor can be divided into heavy belt conveyor, such as mining belt conveyor, and light belt conveyor, such as used in electronic plastics, food, light industry, chemical industry, medicine and other industries. The belt conveyor has the advantages of strong conveying capacity, long conveying distance, simple structure, easy maintenance, and convenient programmed control and automatic operation. The continuous or intermittent movement of the conveyor belt is used to transport articles below 100kg or powdery and granular articles. Its operation is high-speed, stable, low noise, and can be transported up and down the slope.

The belt conveyor can transport all kinds of materials economically and effectively. The belt conveyor can be used in the range of ambient temperature - 20 ℃ to + 40 ℃, and the temperature of transported materials is below 50 ℃. In industrial production, belt conveyor can be used as a link between production machinery and equipment to form continuous production, so as to realize the continuity and automation of production links, improve productivity and reduce labor intensity.

The conveyor belt moves according to the friction transmission principle. It has the advantages of large conveying capacity, long conveying distance, stable conveying, no relative movement between materials and conveyor belt, low noise, simple structure, convenient maintenance, low energy consumption, standardization of parts, etc. Therefore, it is widely used in mining, metallurgy, chemical industry, casting Transportation and production lines in building materials and other industries, as well as production departments such as hydropower station construction sites and ports, are used to transport loose materials or finished goods. According to the requirements of conveying process, it can be transported by a single set, or composed of multiple belt conveyors, or combined with other conveying equipment to form a horizontal or inclined conveying system to meet the needs of operation lines with different layout forms.

working principle:

The belt conveyor is mainly composed of two end rollers and a closed conveyor belt tightly sleeved on them. The drum that drives the conveyor belt to rotate is called the drive drum (drive drum); Another drum that only changes the moving direction of the conveyor belt is called the redirection drum. The driving drum is driven by the motor through the reducer, and the conveyor belt is dragged by the friction between the driving drum and the conveyor belt. The driving drum is generally installed at the discharge end to increase the traction and facilitate the drag. The materials are fed from the feeding end and fall on the rotating conveyor belt. They are transported to the unloading end and unloaded by the friction of the conveyor belt. The scope of application can be used for horizontal transportation or inclined transportation. It is very convenient to use. It is widely used in various modern industrial enterprises, such as underground roadway of mine, surface transportation system of mine, open-pit mining yard and concentrator. According to the requirements of conveying process, it can be transported by a single set, or composed of multiple sets, or combined with other conveying equipment to form a horizontal or inclined conveying system, so as to meet the needs of operation lines with different layout forms.

Key points of design:

1. The working environment, conditions and conditions need to consider the daily operation time, working frequency, service life of belt conveyor, feeding and unloading methods. Working environment and conditions: ambient temperature, outdoor or indoor, environmental protection requirements, moving or fixing, expansion requirements.

2. For the problem of conveying line and belt, the size of conveying line needs to be considered in detail, including inclination, length and lifting height; Dimensions of straight line section and curve section; Connection size, etc. Conveyor belt: sag requirements, simulated friction resistance coefficient and friction coefficient.

3. The specific properties of materials need to be considered for the properties and conveying capacity of materials, including loose density, repose angle, particle size and fragmentation of materials, humidity of materials, wear resistance, adhesion and friction coefficient of materials. Conveying capacity, which can be directly reached when the material flow is uniform. When the material flow is uneven, the basic statistical data of material flow can be considered.

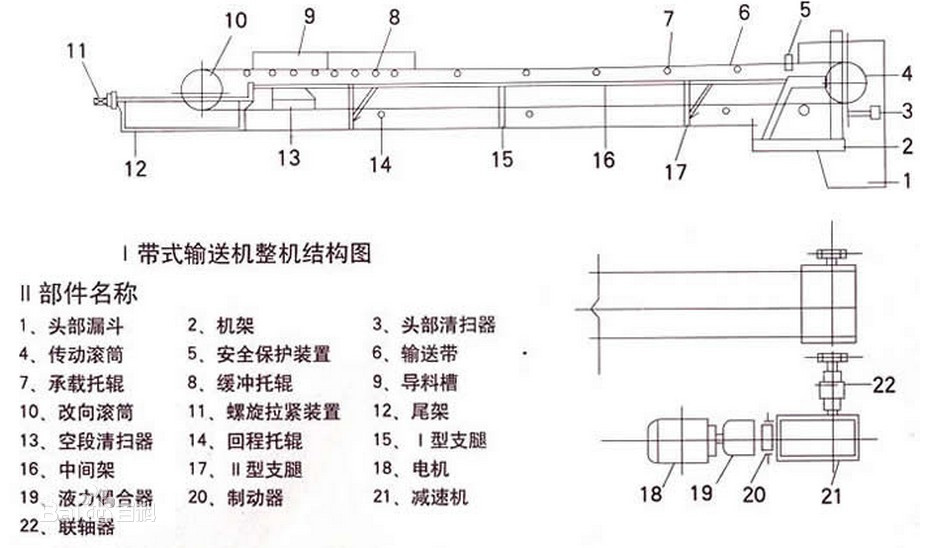

Product composition:

The complete machine of belt conveyor shall include the following parts:

(1) Tape

(2) Idler group

(3) Roller group

(4) Driving device (including motor, reducer, mechanical coupling, driving device base, etc.)

(5) Disc brake

(6) Backstop

(7) Tensioning device

(8) Guide chute

(9) Belt cleaner

(10) Intermediate frame, outrigger, roller support, material receiving plate, guardrail and other steel structural parts

(11) Paint and solvent for on-site paint repair, oil and lubricant for commissioning

(12) All consumables and wearing parts required during installation, commissioning and test run

(13) Special tools, instruments and commissioning instruments for equipment installation, maintenance, inspection and operation

he structure diagram is shown in the figure below:

- Prev:Screw conveyor

- All

- Next:isc feeder