Permanent magnetic separation

- 60s quick Q & A

- 30min reply

- 24h free program

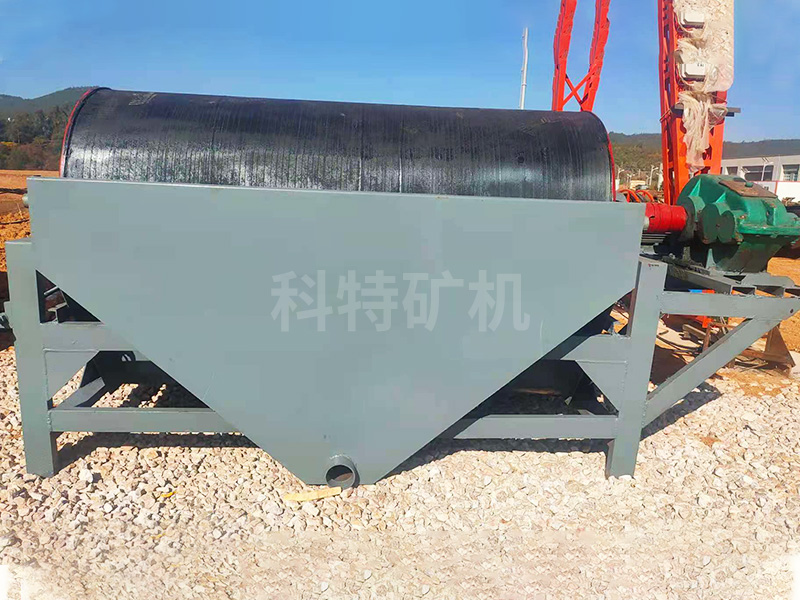

Product introduction:

The separation process of materials in the wet magnetic separator is roughly as follows: after the slurry enters the tank of the magnetic separator through the feeding box, it enters the feeding area in a loose state under the action of water spray pipe (also known as scattered water); Under the action of magnetic field force, magnetic particles are absorbed on the surface of the cylinder and move upward with the cylinder; In the moving process, due to the pole replacement of the magnetic system, the magnetic particles are overturned in chains (called magnetic overturning or magnetic stirring); In the turning process, some non-magnetic particles mixed in the middle of magnetic particles are removed, which is conducive to improving the quality of magnetic products. The magnetic particles move with the cylinder to the weak magnetic field at the edge of the magnetic system and enter the magnetic product tank under the action of flushing water; Non magnetic particles and particles with weak magnetism flow into the non-magnetic product pipe through the hole on the bottom plate under the action of slurry flow in the tank.

Wet magnetic separator features:

The computer optimized design is adopted, the magnetic circuit is reasonable, and the permanent magnet with high coercivity and high remanence is strictly selected to ensure that the magnetism will not be reduced for a long time, protect the long-term interests of users, and the overall structure is reliable and durable.

The tank commonly used in magnetic separation plant is very common in semi countercurrent type!

Semi countercurrent type:

The slurry is fed from its lower part to the lower part of the cylinder. The movement direction of the non-magnetic product is opposite to the rotation direction of the cylinder, and the movement direction of the magnetic product is the same as the rotation direction of the cylinder. The tank with this feature is called semi countercurrent tank. The part of the tank close to the magnetic system shall be made of non-magnetic materials, and the rest can be made of ordinary steel plate or hard plastic plate.

Countercurrent type:

Its feeding direction is opposite to the rotation direction of the cylinder or the moving direction of the magnetic product. The slurry directly enters the lower part of the magnetic system of the cylinder from the feeding box, and the non-magnetic particles and particles with very weak magnetism are discharged from the hole on the bottom plate below the right edge of the magnetic system. The magnetic particles move with the cylinder against the feeding direction to the discharge end of the magnetic product and are discharged into the magnetic product tank. The suitable feeding particle size of the magnetic separator is 0.6 ~ 0mm, which is used in the roughing and scavenging of fine strong magnetic materials. Because the discharge end of the magnetic products of this magnetic separator is close to the feeding port and the magnetic turnover is poor, the quality of the magnetic products is not high, but the discharge port of the non-magnetic products is far from the feeding port. The slurry passes through a long separation zone, which increases the chance of magnetic particles being absorbed. The distance between the discharge ports of the other two products is far, and the possibility of magnetic particles mixing into the non-magnetic products is small, Therefore, this magnetic separator has high recovery rate of magnetic particles.

Downstream type:

The feeding direction of the magnetic separator is consistent with the rotation direction of the cylinder or the moving direction of the magnetic product. The slurry is directly fed into the lower part of the magnetic system from the feeding box, and the non-magnetic particles and particles with weak magnetism are discharged from the gap between the two bottom plates below the cylinder. The magnetic particles are absorbed on the surface of the cylinder and rotate with the cylinder to the edge of the magnetic system where the magnetic field is weak. The magnetic separator is suitable for the roughing and cleaning of coarse-grained strong magnetic materials with particle size of 0.6 ~ 0mm.

Application scope of wet magnetic separator:

Wet countercurrent magnetic separator is applicable to mines, coal preparation plants and other units for wet separation of fine-grained strong magnetic minerals in weak magnetic field, or removal of mixed strong magnetic minerals in non-magnetic minerals. The wet magnetic separator has the advantages of stable separation process, easy control, large allowable variation range of feed concentration, high enrichment ratio, high recovery rate, small floor area, low water consumption, simple structure, large processing capacity, simple installation, convenient operation, small investment and quick effect. Wet separation of fine-grained ferromagnetic minerals, or removal of mixed ferromagnetic minerals in non-magnetic minerals. The wet magnetic separator has the advantages of stable separation process, easy control, large allowable variation range of feed concentration, high enrichment ratio, high recovery rate, small floor area, low water consumption, simple structure, large processing capacity, simple installation, convenient operation, small investment and quick effect.

- Prev:Plate magnetic separation

- All

- Next:no more